[ad_1]

The coronary heart of any electric powered motor consists of a rotor that revolves all-around a stationary portion, called a stator. The stator, customarily built of iron, tends to be heavy. Stator iron accounts for about two-thirds of the bodyweight of a standard motor. To lighten the stator, some men and women proposed making it out of a printed circuit board.

Although the plan of replacing a hunk of iron with a light-weight, ultrathin, easy-to-make, extended-lasting PCB was interesting from the outset, it didn’t attain popular adoption in its earliest apps inside of lawn equipment and wind turbines a little above a ten years ago. Now, even though, the PCB stator is acquiring a new lease on daily life. Anticipate it to conserve pounds and so electricity in just about all the things that employs electrical power to impart motive pressure.

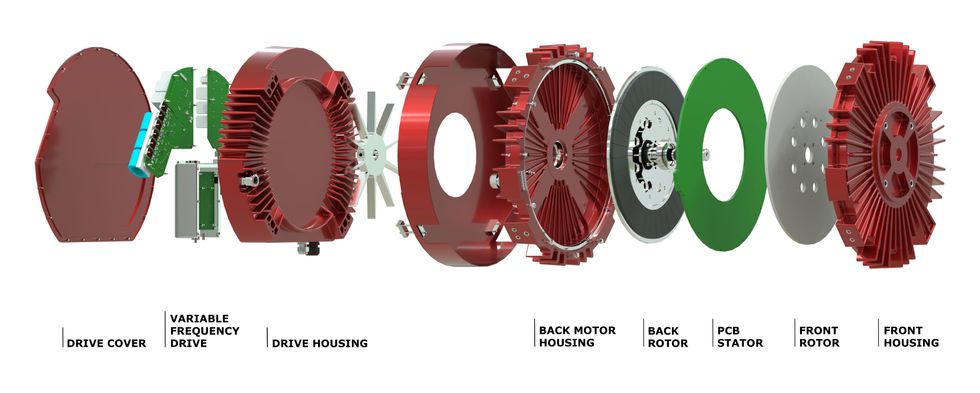

The layered components of an Infinitum Electric axial-flux motor are demonstrated in this article, in exploded type.INFINITUM Electric

This conserving of strength is critically significant: Program may possibly be eating the earth, but electric power is more and more what will make the world go round. Electric powered motors eat

a minimal more than half of the world’s electrical energy currently. Some 800 million motors are now bought every year around the globe, in accordance to the market investigation group Imarc, a amount that has been expanding by 10 percent every 12 months. Electrical motors are producing major inroads into cars, trains, and plane, as perfectly as industrial devices and heating, ventilating, and air-conditioning units. Transportation, construction, and HVAC alongside one another account for about 60 percent of all U.S. greenhouse fuel emissions more effective electrical motors will support minimize emissions in these sectors.

Even with the benefits of the PCB stator, people today ended up slow to embrace the style and design since of a couple misconceptions.

To start with, there was the mistaken belief that PCBs ended up excellent only for delicate applications. But in 2011,

Main Outside Electricity designed a leaf blower and a weed trimmer, both equally of which utilised a PCB stator and still had been rugged as effectively as silent.

Next, there was a perception that PCB stators could be applied only for very low-electrical power devices. But in 2012 Boulder Wind Ability set a PCB stator in a

12-meter-diameter immediate-push generator for a wind turbine that output 3 megawatts of electricity and just in excess of 2 million newton meters of torque. It was a single of the smoothest-jogging higher-ability turbines ever designed.

Neither enterprise endured. Boulder Wind Electric power ran out of funding just before it could safe professional contracts. Core Outdoor Power could not compete in a crowded current market exactly where there ended up less expensive choices. Even now, their pioneering achievements demonstrated the feasibility of PCB stators.

Rapidly-forward to currently. My corporation,

Infinitum Electric powered, of Austin, Texas, has formulated a PCB stator motor that suits a wide variety of functions. Our motor generates as substantially power as a regular alternating-recent induction motor but has 50 % the pounds and size, would make a fraction of the sounds, and emits at minimum 25 % much less carbon. It is now obtaining apps in HVAC, producing, weighty business, and electrical automobiles. Here’s how it will work.

The Infinitum Electric motor is what’s identified as an axial-flux motor, a style in which the stator’s electromagnetic wiring stands parallel to a disk-formed rotor made up of lasting magnets. When alternating present-day flows through, it helps make the rotor spin. The motor also has an air core—that is, there is no iron to mediate the magnetic flux and very little in between the motor’s magnetic areas but slim air. Set all these things together and the final result is an air-main axial-flux permanent-magnet motor.

In the previous, tries to establish these types of a motor faced serious realistic road blocks. A complex manufacturing procedure was needed to construct the stator, the copper windings had been cumbersome, and the coil aid structure was intricate. As a outcome, the air gap was so extensive that only a sizeable magnet mass could create the necessary magnetic flux.

At Infinitum Electrical, we did away with all those copper windings and as a substitute use photolithographic techniques to etch slim copper traces interleaved with epoxy-glass laminate, which insulates every coil from neighboring coils. Getting rid of the iron core and reducing copper with each other conserve 50 to 65 p.c of the weight and 50 to 67 per cent of the volume of the motor, when in contrast to an equal standard iron-main motor. And conveniently, the copper and the laminate grow and agreement similarly as the temperature rises and falls, staying away from worry that may well in any other case gradually pull the components apart.

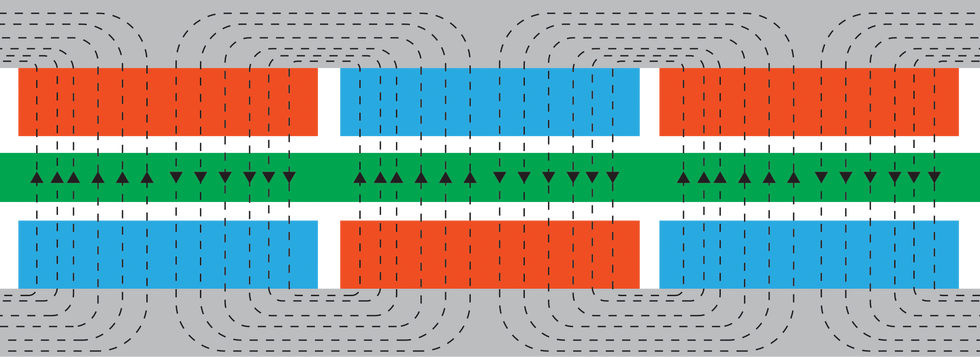

The absence of a stator main lets us to set two identical rotors dealing with each and every other on possibly aspect of the stator, with every rotor carrying highly effective permanent magnets. This arrangement creates a consistent magnetic flux. As in other axial-flux motors, that flux is parallel to the axis of rotation, alternatively than radial. Mainly because the magnetic air gap is narrow, we want only a tiny magnet, which is why we can wring a ton of electricity from a provided mass and quantity.

Our motor generates as much energy as a regular AC induction motor but has 50 percent the body weight and sizing, would make a portion of the noise, and emits at the very least 25 per cent significantly less carbon.

What’s much more, PCBs are produced by an automatic process, which indicates they are a lot much more uniform and trustworthy than hand-wound machines. We produced them even far more reputable by simplifying their topology, which has to do with the motor’s phases.

An electrical phase is an alternating voltage that types a sinusoidal wave that is shifted in time relative to the voltage in a further period. The a variety of phases are synchronized so that the sum of the currents is normally zero. When a multiphase voltage program is applied to a motor that has a individual winding for every single section, the circulation of numerous currents generates a magnetic field that rotates in space. The conversation of this rotating area and the discipline made by rotor magnets is what turns the rotor.

Previous PCB stators mixed the copper traces from unique phases in the exact layer, which established the opportunity for small circuits. We alternatively have each individual layer have only just one electrical section, and we limit the amount of connections involving layers. That arrangement offers a steady route for the electric existing and minimizes the chance of electrical failures.

Another edge of the new layout is the independence it provides designers to connect coils possibly in collection or in parallel. Connecting the coils in collection is correct for three-phase industrial purposes and following-era electric powered vehicles. Connecting in parallel is greater for minimal-voltage apps, this kind of as in an auxiliary EV motor.

Like other long term-magnet motors, our axial-flux motor needs a variable frequency travel to efficiently start and speed up the motor to the desired pace. The VFD also controls the speed and torque as demanded by the application.

A shorter route for magnetic flux is made probable by sandwiching rotors [gray] with magnets [red and blue] all around a thinly printed circuit board stator [green].

However, the air-main layout gives the motor exceptionally reduced impedance (commonly just 5 to 7 % as significantly as in a typical iron-core motor), for the reason that air are unable to contain as considerably magnetic strength as iron can. There is so very minor magnetic electricity available to smooth out the variations in the voltage supplied to the motor by the VFD. To cure this deficiency, we extra yet another ingredient: an integrated variable frequency drive that is great-tuned to function with a minimal-impedance motor. Our VFD works by using substantial-efficiency silicon carbide MOSFETs, which cut down losses and add to overall program performance.

The VFD also monitors efficiency, and the effects can be noted via the cloud, if the consumer needs. The motor’s program can also be up to date in this manner. This kind of distant monitoring offers a selection of ways to preserve energy, handle performance, and forecast when maintenance may possibly be needed.

The thinness of the PCB furnishes a superior floor-to-volume ratio, which can make for a lot more productive cooling, consequently enabling us to push two to three times as significantly current for a offered sum of copper. The cooling can be finished by blowing air over fins on the exterior of the motor and across the electronic compartments.

Eradicating the iron core eradicates decline because of to the cyclical magnetization and demagnetization of the iron, whilst also steering clear of vitality-losing eddy currents in the steel. Our air-core motor can as a result run at a superior performance above masses ranging from 25 percent to 100 p.c of the rated electric power. Skipping the iron main also usually means the magnets on the rotors experience a constant reluctance and a regular magnetic industry as the rotor turns. This arrangement gets rid of eddy-recent losses in the magnets and the rotors, which thus can be made of common, unlaminated, lower-carbon steel plates.

In a common electrical motor, both of those the stator and rotor are manufactured of ferromagnetic products. After electric powered currents are applied and rotating magnetic fields are proven, these fields deliver two forces: one particular that makes useful torque and will cause the rotor to rotate, and yet another that pulls the rotor radially toward the stator. This radial pressure does very little practical, and it aggravates sounds and vibration, simply because the slots in the stator—needed to accommodate the copper coils—generate pulses.

Here’s why that happens: A magnetic flux creates a power that at to start with points in the same path the rotor is shifting in then, as the rotor turns, the alignment of the rotor poles alterations in relation to the stator slots right until the power factors in the reverse way. This alternating pressure creates torque ripples, which can lead to metal exhaustion in the motor and in the equipment that it is driving.

But there is no this sort of alternating magnetic drive in the Infinitum motor. This advantage, collectively with other efficiencies, is why its sounds averages about 5 decibels lower than that of conventional motors. That might not appear to be like a lot of a reduction, but this ingredient of motor sound tends to be at a specifically bothersome pitch.

By combining the lightness of an air-main motor with the large torque density of an axial-flux machine, the Infinitum motor is very well suited for building air flow and HVAC programs. That’s significantly useful now that the pandemic has place a precedence on purifying indoor air. Warmth pumps, which warmth and neat in one process, are a further software in which the motor can save power, relieve set up, and decrease sounds. According to

latest tests done by the U.S. General Solutions Administration and the U.S. Division of Electrical power, Infinitum Electrical motors could save up to US $8 million yearly if deployed in the GSA’s HVAC plants.

Electric powered vehicles are a different significant sector for this new motor. EVs are projected to make up 31 p.c of the worldwide fleet by 2050, according to the

U.S. Energy Facts Administration.

Our business is working with a foremost automotive supplier to develop an oil-cooled motor for a very long-selection hybrid car or truck. Oil cooling works a lot far more proficiently in our structure than in a regular motor simply because the coolant can be quickly utilized to the entire area of the PCB. With oil cooling, we have realized a threefold enhance in power density around our own air-cooled motor, bringing the energy density into the 8 kilowatt/kilogram to 12 kW/kg variety. That can make the oil-cooled variation ideal for use in electric powered aviation, yet another promising market.

We’re also doing the job with companies that specialize in substance dealing with, this sort of as forklifts, conveyor techniques, and the mixing equipment that is utilized to make foodstuff and drinks.

Caterpillar Enterprise Cash has invested in Infinitum Electrical to create a new line of alternators that are one-3rd the size and pounds of present versions and quieter and a lot more economical as properly. The alternator current market is approximated at $17 billion a calendar year and escalating.

We estimate that if each motor in the environment were being changed by an Infinitum Electric powered motor, it would decrease carbon emissions by 860 million tonnes for every year. That’s the equivalent of eradicating the emissions from 200 million automobiles yearly. As motors turn into ubiquitous, even tiny improvements in efficiency have the electrical power to make a large variation for our planet nowadays and above the up coming century.

This report appears in the April 2022 print situation as “This Axial-Flux Motor With a PCB Stator Is Ripe for an Electrified Environment.”

From Your Web page Articles

Relevant Article content All over the Internet

[ad_2]

Source hyperlink

More Stories

Education Technology Integration – Computer Microscopes Are Enhancing the Science Classroom

History: Computers Components and Technology

Considerations for Selling Used Computers